EOT Crane Design Calculation

EOT Crane Design Calculation

Single girder EOT Crane mainly has three types, customers can choose according to different needs of different types of crane.

LD Single Girder Overhead Crane

1.Capacity:1ton-20ton

2.Span:7.5-31.5m

3.Max. lifting height:28.5m

4.Working duty:A3-A4

5.Power supply: 380v-50hz,3Phase A.C.

or as your request

LX model double girder overhead crane

1.Capacity:0.5ton-10ton

2.Span:3m-16m

3.Max. lifting height:18m

4.Working duty:A3

5.Power supply: 380v-50hz,3Phase A.C.

or as your request

LDP Single Girder Overhead Crane

1.Capacity:3ton-16ton

2.Span:7.5-31.5m

3.Max. lifting height:30m

4.Working duty:A3-A5

5.Power supply: 380v-50hz,3Phase A.C.

or as your request

EOT Crane Design Calculation

The crane girder is of welded girder construction. This result in lower dead weight with a high degree of vertical and horizontal rigidity and small wheel loads being transmitted to the crane runway.

Control method: Pendent line with press button or remote control or both

Painting: Primer and finishing paint

Color: According to your demand

Average thickness: About 100 microns

EOT Crane Design Calculation

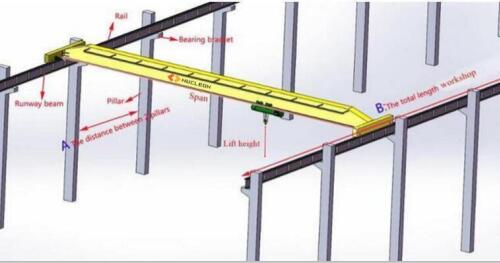

- Main beam – The main traveling structure of the crane which spans the width of the bay and travels in a direction parallel to the runway. The bridge consists of two end trucks and one or two bridge girders depending on the equipment type. The bridge also supports the trolley and hoisting mechanism for up and down lifting of load.

- End trucks – Located on either side of the bridge, the end trucks house the wheels on which the entire crane travels. It is an assembly consisting of structural members, wheels, bearings, axles, etc., which supports the bridge girder(s) or the trolley cross member(s).

- Bridge Girder(s) – The principal horizontal beam of the crane bridge which supports the trolley and is supported by the end trucks.

- Runway – The rails, beams, brackets and framework on which the crane operates.

- Runway Rail – The rail supported by the runway beams on which the crane travels.

- Hoist – The hoist mechanism is a unit consisting of a motor drive, coupling, brakes, gearing, drum, ropes, and load block designed to raise, hold and lower the maximum rated load. Hoist mechanism is mounted to the trolley.

- Trolley – The unit carrying the hoisting mechanism which travels on the bridge rails in a direction at right angles to the crane runway. Trolley frame is the basic structure of the trolley on which are mounted the hoisting and traversing mechanisms.

- Bumper (Buffer) – An energy absorbing device for reducing impact when a moving crane or trolley reaches the end of its permitted travel, or when two moving cranes or trolleys come into contact. This device may be attached to the bridge, trolley or runway stop.

Nucleon Crane Group is china famous Single girder Overhead Crane Manufacturer and double girder Overhead Crane Manufacturer.

See more:http://www.nucleoncranegroup.com

http://www.nucleonoverheadcrane.com

Email:info@nucleoncranegroup.com

If you have any questions, Please don’t hesitate to contact me.