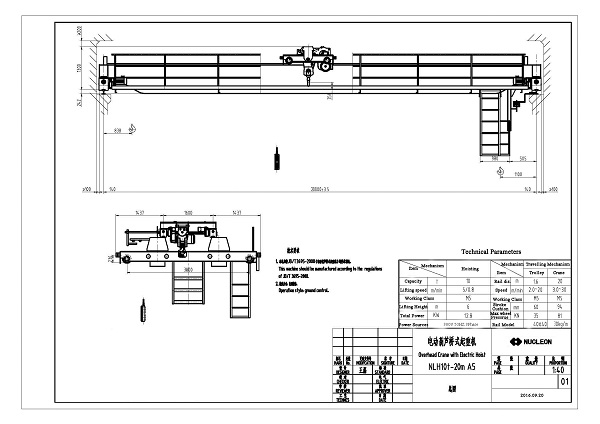

NLH Double Girder Overhead Crane

NLH Double Girder Overhead Crane

NLH Double Girder Overhead Crane is designed, manufactured and inspected in accordance with relevant national standards, and equivalently adopt some foreign standards such as FEM, DIN, IEC, etc.Compared with the original general-purpose QD bridge crane products, the self-weight is reduced by about 15-30%, and the wheel pressure is reduced by about 10-35%, which can reduce the crane’s requirements for the plant structure and save the plant’s manufacturing cost.

Double Girder European Traveling Overhead Crane Advantages:

(1)Light self-weight

Design software developed by the company combine with three-dimensional modering and finite-element analysis, apply the reasonable structure to lifting mechanism, steel construction and accessories, together with wide use of high-strength material, it increases load capacity, decreases self-weight and has lower weight and wheel pressure than that of traditional crane.

(2)Small space use

Limit distance from hook to boat sides is short but has large working arrange. with lower height above the rail, it makes full use of space of factory building,

(3)Low cost of running and maintaining

As with low wheel pressure and small dimension, it reduces investment of previous construction including factory building, and also reduces illumination and heating expense. The reilable performance and durability also minimizes the additional charges for the use of product at the later stage. Selected components with high quality and preformance lower the maintenance and repair. The total power consumption is reduced, which achieves cost savings.

(4)High performance

Use variable-frequency technology, run with heavy load at low and light load at high speed. The adjustable speed ranges in 1:10, which ensures crane run steadily and reduces impact on factory building. Combination of swing-proof technology achieves a high accuracy position of lifting items.

NLH Double Girder Overhead Crane Specifications

| Lifting Capacity | T | 5 | 10 | 16/3.2 | 20/5 | 32/5 | 50/10 | ||

| Span | m | 10.5-31.5 | |||||||

| Speed | Main Hook Lifting | A5 | m/min | 11.3 | 8.5 | 7.9 | 7.2 | 7.5 | 5.9 |

| A6 | 15.6 | 13.3 | 13 | 12.3 | 9.5 | 7.8 | |||

| Aux. Hook Lifting | 16.7 | 19.5 | 19.5 | 10.4 | |||||

| Traveling of Trolley | 37.2 | 43.8 | 44.6 | 44.6 | 42.4 | 38.5 | |||

| Traveling of Crab | A5 | 89.8/91.8 | 90.7/91.9 /84.7 |

84.7/87.6 | 84.7/87.6 | 87/74.2 | 74.6 | ||

| A6 | 92.7/93.7 | 115.6/116 /112.5 |

112.5/101.4 | 112.5/101.4 | 101.4/101.8 | 75/76.6 | |||

| Operational Model | Cabin; remote control; ground handle | ||||||||

| Working Duty | A5,A6 | ||||||||

| Power Supply | Three-phase A.C. 380V, 50Hz or customized | ||||||||