Electric hoist motor

Selection and verification of motors for hoist

Introduction: The choice of motor mainly refers to the choice of heat capacity, which includes the motor overload capacity calibration and heat verification. Overload capacity check is to check the motor customer service agencies may occur in a short time, the greater the workload of the ability, and heat verification is to verify that the motor running for some time after the winding temperature rise exceeds the allowable temperature rise.

This paper describes the selection and calibration of the motor in detail, based on the primary selection and calibration contents of the motor for the hoist. Finally, give a simple example of how to select and verify the motor steps and methods.

First, the electric hoist motor capacity selection

Electric hoist motor is to start the inertia load is small, the required acceleration torque is very small, only 10% -20% of the full load and stable operating torque, while the motor is usually the average aerodynamic torque of the motor rated torque 1.6-1.8 times, Making the start-up time is short (about 1-2S or so). Therefore, the hoisting mechanism motor can ignore the start process during operation, that the motor is running S3 system.

1, primary electromotor in the hoisting mechanism, the motor torque is equal to the required full-load lifting stability torque. The motor power can be calculated from the lifting power

PN = PQ × Vq / 1000 / η

Where PQ – lifting load (N)

Vq-rated lifting speed (m / s)

Η-total mechanism efficiency.

2, the calculation of S3, JC = 40% of the standard operating system required motor power: Pn ≥ PKN

Where: K – operating frequency coefficient, and the corresponding agent work level

Pn – S3, JC = 40% of the rated motor power.

3, the motor in different working system under the power value conversion

The motor power value converted to S1 JC = 40% or S3 JC = 60% of the motor power value in the S1 operating system can be converted to the following formula:

P40~1.15 to 1.2 PS1 P60~1.05 to 1.1 PS1

For different motors, the conversion factor is slightly different, if you want to know the exact conversion value, should be obtained from the manufacturer.

For the double rope grab hoisting mechanism and opening and closing mechanism, generally use two sets of the same drive mechanism. After the hoisting of the grab closed, all the load has a closed motor to bear. Support the motor due to unloading and speed increased, and finally to catch up with the motor and bear . So the same size of the two motor power rating needs more than half of the required power, closed motor has a short time overload capacity. Norms, each institution of the motor power value of 0.66 times the total power, is to consider the lifting moment of the load unevenness.

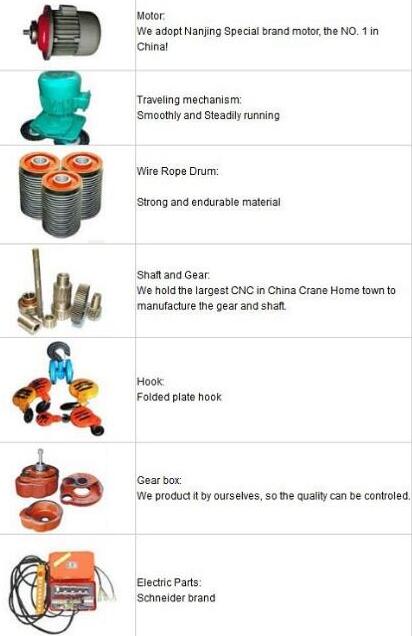

Electric hoist is one of our main products. We can supply various electric hoist for crane.

For more details, please contact us via info@nucleoncranegroup.com