FEM Standard Overhead Crane

Single Girder FEM Standard Overhead Crane

The Single Girder FEM Standard Overhead Crane could be widely used to handle materials in many industries’ workshop and warehouse. Such as machinery manufacture, warehouse, logistic, food, paper making, electronics industries workshop and other material handling situations. The lifting hoist adopts M5 working class with double lifting speed. motor with ABM German brand motor. Travelling motor uses SEW European brand in one motor gear motors. Cross and long traveling are variable travelling speed. Electric parts adopt Siemens brand. The protection class is IP 54 high class. The working class can reach to A5/M5 class under ISO standard.

FEM HOIST

Compact lightweight hoist (30% space saving, 40% energyefficiency) compliant with FEM/CE, ideal for low-clearance workshops, automated lines, and preci- sion manufacturing.

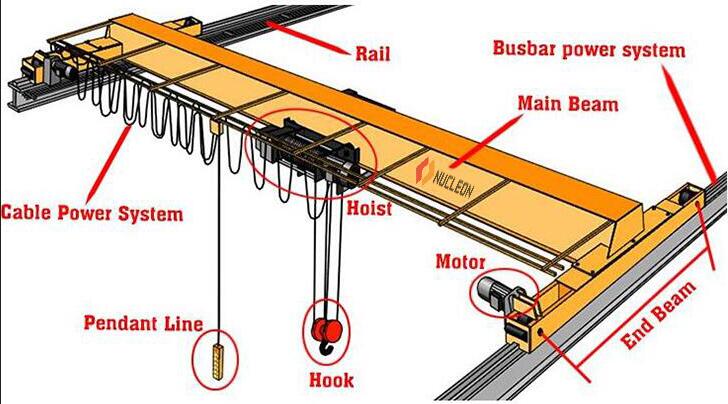

END GIRDER

Connects main girder, forms bridge support, stable structure, easy install/transport, ensures stability.

MAIN GIRDER

Main load-bearing structure, high-quali- ty steel, professional manufacturing, strong capacity, supports weight, ensures strength.

REMOTE CONTROL

Long control distance, easy/flexible operation, keeps operators safe, improves convenience.

HOOK

High-strength material, key for load-bearing, safety-standard design, anti-deformation, reliable lifting.

WHEEL

Wear-resistant material, supports move- ment, stable/smooth running, reduces

friction, ensures track stability, longer life.

Description:

Europe overhead crane advanced designed crane for the low headroom and high lifting height demands. It has many advantages such as: Strong rigidity, light dead weight, outstanding structure design, long working lift etc. It could save your factory space and investment effectively.Its technology is advanced and design is based on international standard: DIN (Germany),FEM (Europe), and ISO (International) The all motions of this overhead crane are double speeds, the lifting motor is double speed type,the cross travelling motor and long travelling motor are controled by frequency inverte It could be widely used to handle materials in many industries’ workshop

and warehouse,such as manufacture processing, warehouse, storage, paper mill, electronics industries workshopand other material handling situation

| Capacity (t) | Span (m) | Lift height (m) | Work duty(FEM) | Lift speed (m/min) | Trolley speed (m/min) | Crane speed (m/min) | Max. wheel load (kn) |

| 3.2t | 4-31.5 | 6-18 | 2M、3M | 5/0.8 | 5.0-20 | 3.0-30 | 30.8-61.8 |

| 5t | 7-31.5 | 6-18 | 2M、3M | 5/0.8 | 5.0-20 | 3.0-30 | 35.8-69.8 |

| 10t | 7.5-31.5 | 6-18 | 2M、3M | 5/0.8 | 5.0-20 | 3.0-30 | 60.5-100.5 |

| 16t | 7.5-31.5 | 6-18 | 2M、3M | 4/0.6 | 5.0-20 | 3.0-30 | 93-144.3 |

| 20t | 7.5-31.5 | 6-18 | 2M、3M | 4/0.6 | 5.0-20 | 3.0-30 | 112-140.2 |

| 32t | 7.5-31.5 | 6-18 | 2M、3M | 3.3/0.8 | 5.0-20 | 3.0-30 | 84-117.6 |

| 50t | 7.5-31.5 | 6-18 | 2M、3M | 0.5-3.2 | 5.0-20 | 3.0-30 | 136-180 |